Computer temperature measurement of mass concrete£¨First line communication£©System manual

(Date of last amendment£º2005.2.25)

System hardware connection

Computer temperature measurement of mass concrete£¨First line communication£©The system is one of the most sold products£¬The main reason is the low price¡¢Good real-time performance¡¢Small operation workload¡¢Easy installation¡¢Product maturity£¬So special recommendation¡£

According to the actual situation of all users£¬Not a single project£¬All equipment investment can be recovered.¡£Because in addition to sensors£¬The rest is reusable£¬In the future, there is no need to invest in these hardware devices.¡£

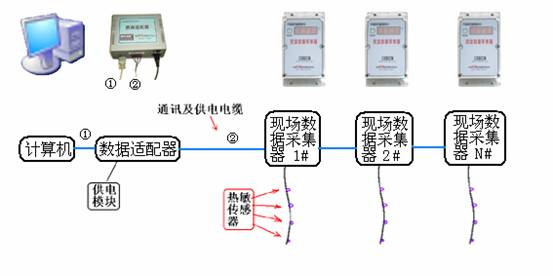

One¡¢Computer temperature measurement of mass concrete£¨Wired£©Composition of the system£º

The system consists of£ºUser computer¡¢Computer monitoring software¡¢Data adapter£¨Power supply system¡¢Data transceiver£©And power transmission line¡¢Field data collector¡¢Sensor composition£»Optional devices are£ºUSBturn232Modular¡£

Two¡¢Brief introduction of each part£º

¡¾Power supply module¡¿Responsible for¡¾Data adapter¡¿And each¡¾Field data collector¡¿power supply£¬¡¾Power supply module¡¿Already installed to¡¾Data adapter¡¿in¡£¡¾Data adapter¡¿Be responsible for¡¾Computer¡¿And each¡¾Field data collector¡¿Data communication between£¬¡¾Data and power transmission line¡¿Will each¡¾Field data collector¡¿and¡¾Data adapter¡¿Tandem up£¬Function of data transmission and power supply£¬The line should use£´Core cable£¬The cross-sectional area of each core wire shall not be less than£±Square millimetre¡£¡¾Computer¡¿Software passing¡¾Data adapter¡¿Control and data transmission of£¬Can control each¡¾Field data collector¡¿Operation£¬And collect each¡¾Field data collector¡¿Measurement data of£¬Then summarize¡¢Handle£¬Save to database£¬And it can be dynamically displayed in real-time on the screen graph curve.£¬The software can print out graphs, reports, etc.¡£

¡¾Field data collector¡¿At the same time, it provides the function of displaying temperature data on the spot.¡£It provides convenience for construction personnel¡£If you want to display temperature measurement data on site£¬Just press¡¾Field data collector¡¿Upper¡¼display¡½Button¡£

One¡¾Field data collector¡¿Can be connected at the same time1¡«8individual¡¾Thermal sensor¡¿¡£

Three¡¢install£º

According to the construction plane£¬What a site needs¡¾Field data collector¡¿Different quantity£¬Most of the time6~24only¡£

Field installation can be carried out before or at the same time as concrete pouring£¬Installation difficulty and workload are not large¡£

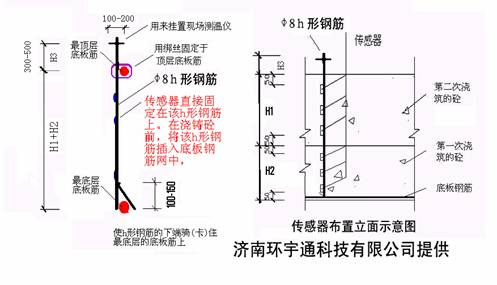

£±£®¡¾Thermal sensor¡¿According to¡¶Temperature measurement plan¡·Design height of£¬Binding to field madehOn the steel bar for fixing£¬Insert vertically to the position to be tested before pouring concrete£¬After pouring concrete£³¡ª£µhour£¬Can be placed¡¾Field data collector¡¿And will¡¾Thermal sensor¡¿The outgoing end of the£¬link up¡¾Data and power transmission line¡¿Can work¡£

£²£®¡¾Field data collector¡¿reach¡¾Data adapter¡¿Between¡¾Data and power transmission line¡¿Necessary protection is needed£¬Prevent rolling off during construction¡£¡¾Data adapter¡¿Between¡¾Data and power transmission line¡¿Placed in the concrete without setting£¬Generally, no special treatment is required.¡£(notes£º¡¾Data and power transmission line¡¿also known as¡¾data bus¡¿¡£)

User computer is provided by user£¬Recommended configuration as long as it workswin98sethat will do£¬In addition, there must be at least one serial port£¨or£¨and£©Oneusbmouth£©¡£

¡¾Data and power transmission line¡¿£¨Also known as data bus£©£ºSelf matching according to actual length£¬yes4Core cable£¬The cross-sectional area of each core shall not be less than1Square millimetre¡£

The following is the connection diagram of the whole system£º

Of¡¾Field data collector¡¿

![]()

nField data collector£º

The¡¾Field data collector¡¿The number and location of each sensor terminal block are indicated on the(The front row is from left to right£º1-1,3-3,5-5,7-7£¬The back row is from left to right£º2-2,4-4,6-6,8-8)£¬Be careful£¬Sensors do not distinguish between positive and negative polarity¡£The unused sensor terminals are empty¡£

The¡¾Field data collector¡¿It also indicates the wire sequence number of the terminal to be connected to the data bus.(A¡¢B¡¢C¡¢D)£¬Be-all¡¾Field data collector¡¿Data bus terminal block of£¬Must be connected to the system¡¾data bus¡¿£¬And it needs to be differentiated(A¡¢B¡¢C¡¢D)Line order¡£

Systematic¡¾data bus¡¿yes4Core cable£¬Each core section of the cable shall begreater than1Square millimetre£¬If the core section is too small£¬It will cause the increase of measurement error and the failure of data transmission.¡£General4The core cable has different colors£¬Good for differentiation(A¡¢B¡¢C¡¢D)Line order¡£Please note that£ºTo avoid short circuit£¬When wiring, the computer terminal¡¾Data adapter¡¿Upper¡°Power switch¡±Put¡°Close¡±state¡£

When each¡¾Field data collector¡¿Connected to the system bus£¬And it's already connected with the computer¡¾Data adapter¡¿After the bus terminal is connected£¬If the¡¾Data adapter¡¿Upper¡°Power switch¡±open£¬each¡¾Field data collector¡¿There should have been a power supply.£¬Then£¬Just press each¡¾Field data collector¡¿On the panel¡°Display button¡±£¬That is to say¡¾Field data collector¡¿HardwareID,And the measured temperature of each sensor£¬The display contents are as follows£º

for example£ºPress each¡¾Field data collector¡¿On the panel¡°Display button¡±£¬Similar content will be displayed in sequence as follows£º

display£º3001 ßShow that¡¾Field data collector¡¿HardwareID£»

display£º---- ßdisplay4individual¡°-¡±Number£»

display£º1=24 ßShow measured1#The temperature value of the sensor is24¡æ£»

display£º2=25 ßShow measured2#The temperature value of the sensor is25¡æ£»

display£º3=26 ßShow measured3#The temperature value of the sensor is26¡æ£»

display£º4=27 ßShow measured4#The temperature value of the sensor is27¡æ£»

display£º5=28 ßShow measured5#The temperature value of the sensor is28¡æ£»

display£º6=29 ßShow measured6#The temperature value of the sensor is29¡æ£»

display£º7=30 ßShow measured7#The temperature value of the sensor is30¡æ£»

display£º8=E1 ßShow measured8#Sensor open or short or not in use£»

in addition£¬Will be displayed when communicating with the computer4Equal sign£º==== ¡£

According to the requirements of some users£¬The measurement range of this system has been extended to-19¡æreach129¡æ£¬An example of showing a negative temperature is as follows£º

display£º3-16 ßShow measured3#The temperature value of the sensor is-16¡æ£»

display100¡æExamples of the above temperatures are as follows£¨Equal sign and hundred digit number1Share one digital tube=|£©£º

display£º3=|24 ßShow measured3#The temperature value of the sensor is124¡æ£»

|

|

|

£¨Data cable connection between data adapter and computer£© |

|

|

|

£¨Data adapter£© |

|

|

|

£¨Wiring in field collectors£¬On the left is the sensor.£¬The connection on the right is the data bus£» Please note that£ºThe data bus is sequential£¬useABCDExpress£© |

|

|

|

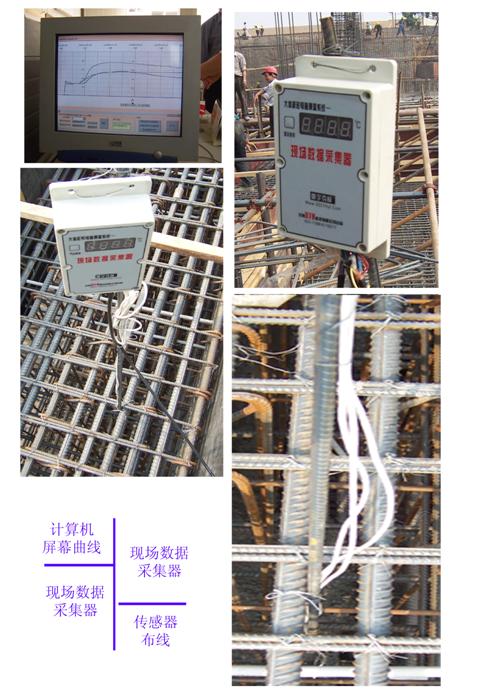

£¨Local pictures and connection drawings£© In this picture:¢ÙRepresents the data line between the computer and the data adapter; ¢Úand¢æAll represent the data bus of four core cable; ¢ÛIndicates the location of the sensor. |

£¨Be careful£ºDue to device upgrade£¬The device in the picture may be different from the actual device£©

¡¾Field data collector¡¿When used on site£¬Can be placed in a wooden protective box£¬The sensor wire and data bus are threaded through the reserved holes of the wooden box.£¬And insert it to¡¾Field data collector¡¿On the corresponding terminal socket¡£Again¡¾Field data collector¡¿Fixed in wooden box with screws¡£Wooden box fixed onhTop of T-bar¡£Wooden boxes can be made on site£¬The structure can be made with reference to the figure below£º

£¨chart£ºWooden protection box£©

About the computer side¡¾Data adapter¡¿

nComputer side¡¾Data adapter¡¿£º

¡¾Data adapter¡¿Next to the computer£¬¡¾Data adapter¡¿The bus terminal of is connected with the data bus£¬DistinguishA¡¢B¡¢C¡¢Dorder¡£

¡¾Data adapter¡¿There is one.9Empty serial terminal¡£Please use the supplied¡¼Special serial port connection¡½£¬Connect it to the9Pin to serial connection¡£Please note that£¬There are usually1reach2Serial port£¬In use¡¼Special serial port connection¡½You must turn off the computer's power and¡¾Data adapter¡¿Power supply¡£

(chart:Special serial port connection)

You can also use the¡¼Special serial port connection¡½connection to¡¾Data adapter¡¿Upper9Empty serial port terminal£¬¡¼Special serial port connection¡½The other end of the is connected to the¡¼USBInterface line¡½Of9Pin port£¬Reuse¡¼USBInterface line¡½OfUSBPort to connect to the computerUSBport¡£

£¨chart£ºUSBSerial port line£©

However£¬Use¡¼USBInterface line¡½Must¡°installUSBInterface line driver¡±£¬As shown in the figure£º

in addition£¬If there is no serial port on the computer£¬Can only be usedUSBMouth and special¡°USBInterface line¡±To solve¡£

¡¾Data adapter¡¿There is also a mains connection on the£¬Please use the supplied¡¼Power supply connection¡½£¬connection to220Volt on the mains¡£Please note that£¬In use¡¼Power supply connection¡½take¡¾Data adapter¡¿Before connecting to the mains£¬¡¾Data adapter¡¿Upper¡¼Power switch¡½Already in¡°Close¡±Location¡£

¡¾Data adapter¡¿There is also a power indicator on the£¬Used to indicate the switch status of the power supply¡£

¡¾Serial port on computer¡¿:

£¨chart£ºSerial port on computer£¬And serial port connection£©

On the back of the computer£¬With keyboard socket¡¢Printer jack£¨Parallel port£©¡¢Display data socket, etc.£¬One of them(Or two.)Nine pin socket£¬It's computer.9Pin serial port,

If¡¾Data adapter¡¿And computer use9For serial connection,that9One end of the pin serial port line is connected to it¡£Please note that£¬Plugged9Before the pin serial port line£¬Be sure to turn off the computer£¬Failure to do so may cause damage to your computer£¡

UseUSBInterface line time,No longer using computers.9Pin serial port¡£

Computer software

nRunning environment of software£º

This software can be installed and run on the computer with the following software platform installed£º

£×indows98Se/WindowsMe/Windows2000/WindowsXP/Vista

At least one serial communication port is required on the computer running this software£¬If you don't have a serial port on your computer£¬have access toUSBmouth£¬Please consult our technical department for details¡£

nSoftware installation and uninstallation

nSoftware installation:

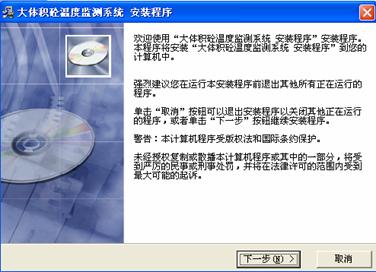

In the software installation CD£¬find¡°Mass concrete temperature monitoring system¡± £¨Pictured£©£º

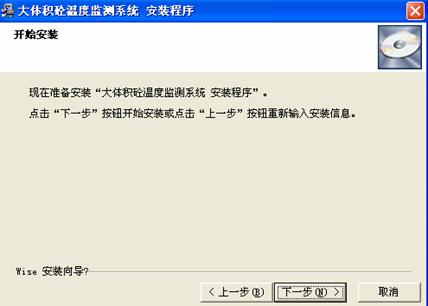

Click to install£¬Enter the installation interface£º

Single click¡¾cancel¡¿Button£¬Then exit this setup program¡£Single click¡¾Next step¡¿Button to go to the next step of setup¡£The picture is as shown in the figure£º

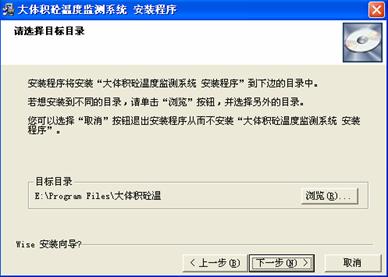

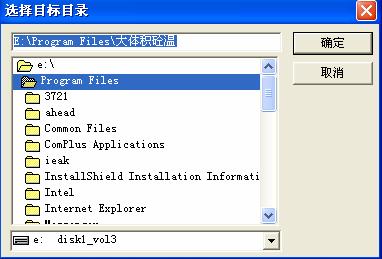

Click¡¾cancel¡¿Button£¬Then exit this setup program¡£Click¡°Previous step¡±Button to return to the previous installation interface¡£If you need to change the installation directory£¬Please click first."browse"Button£¬Can be displayedWindowsStandard dialog£¬To choose the installation path you want£¬And press¡°Determine¡±Button¡£Pictured£º

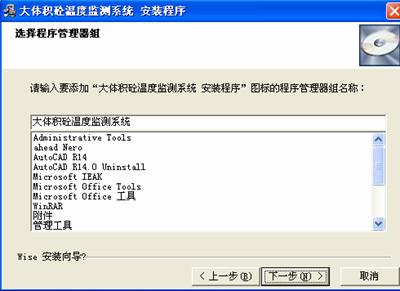

Single click"Next step"Button£¬Get into¡°Select program manager group¡±Interface£º

click¡°Next step¡±Button£¬Until the installation progress bar appears£º

The installation progress bar behaves at different speeds in different systems£ºstayWindows98Se/MeFast installation in the system¡£stayWindows2000andWindowsXpSystem£¬Installation progress bar to100%In the future£¬Long time for software setting and adjustment£¬It's normal£¬Please wait patiently¡£

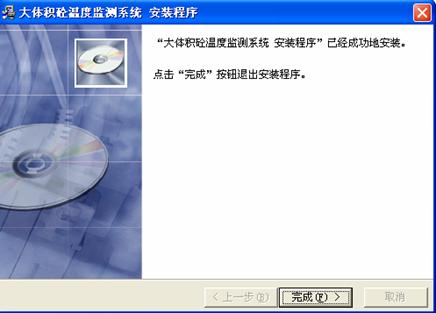

After successful software installation£¬The following prompt window will appear£¬Please click¡¾complete¡¿Button¡£

nSoftware uninstallation£º

If you want to uninstall the software£¬Please use¡°Control panel¡±Upper¡°Add to/Delete program¡±Of¡°install/uninstall¡±attribute£¬Find the application name of the software in the list box£¬click¡°Add to/delete¡±Button£¬To uninstall the software¡£

You can also use the methods described below£¨Or steps£©Uninstall the software£º

¡¡¡¡1. Single clickwindowsDesktop¡¾start¡¿Button£¬Appear¡¾start¡¿menu£»

¡¡¡¡2. Single click¡¾start¡¿Menu¡¾program¡¿£¬Appear"program"cascading menu£»

¡¡¡¡3. from"program"Cascade menu click to include application¡¾Mass concrete temperature monitoring system¡¿Folder£»

4. Click the program you want to uninstall¡¾Temperature monitoring system for unloading mass concrete¡¿¡£

Select from the interface¡°automatic¡±option£¬click¡°Next step¡±Button£¬Follow the prompts¡£

nUse of software

nstart-up

You can use the methods described below£¨Or steps£©Start the software

£ÁUse menu£º

¡¡¡¡1. Single clickwindowsDesktop¡¾start¡¿Button£¬Appear¡¾start¡¿menu£»

¡¡¡¡2. Single click¡¾start¡¿Menu¡¾program¡¿£¬Appear"program"cascading menu£»

¡¡¡¡3. from"program"Cascade menu click to include application¡¾Mass concrete temperature monitoring system¡¿Folder£»

¡¡¡¡4. Click the program you want to launch¡¾Mass concrete temperature monitoring system¡¿¡£

BUsing shortcuts£º

You can click directly on the desktop¡°Mass concrete temperature monitoring system¡±Shortcut

nBoot interface

£¨Boot interface£©

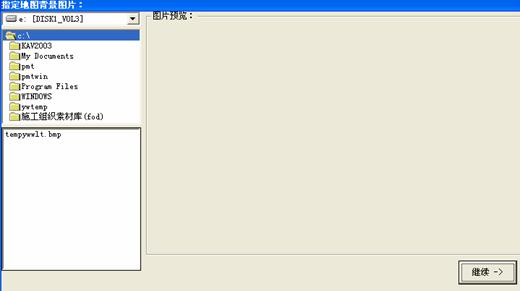

Enter in password£ºyanwei£¬click¡°Determine¡±£¬Enter the following login interface¡£Ad locum£¬Choice¡°conventional landing¡±£¬Enter the main operation interface directly£¬If choose¡°system maintenance¡±£¬Enter system maintenance¡°Specify background picture¡±Interface¡£

Enter in password£ºyanwei£¬click¡°Determine¡±£¬Enter the following login interface¡£Ad locum£¬Choice¡°conventional landing¡±£¬Enter the main operation interface directly£¬If choose¡°system maintenance¡±£¬Enter system maintenance¡°Specify background picture¡±Interface¡£

You can specify a background image here£¬Act as¡°Main interface¡±Base map£¬The background picture is preferably the plan of the bottom plate to be tested£¬Picture pixel size should be greater than600£Ø800Pixels are good.£¬The picture format can bebmp¡¢jpgEtc.¡£Set picture in¡°Picture preview¡±Box to preview¡£

click¡°Continue¡±Get into¡°Set up¡±window¡£

nSetup window

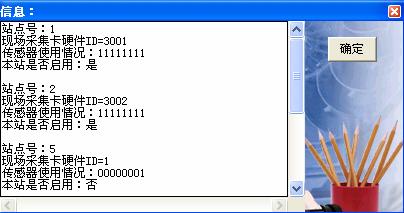

In the settings window£¬Provides the location of the set test point¡¢Parameters and other functions¡£

among£º

nAdd monitoring points After pressing this button£¬Move the mouse in the settings screen on the left£¬

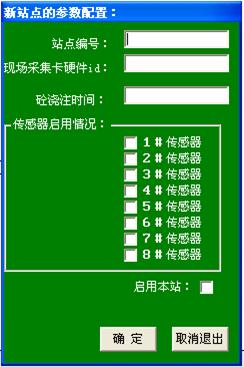

And shock the mouse in a proper place.£¬A new site will appear£¬And the parameter configuration screen of the site will pop up.£º

Set the following data here according to the actual situation£º

Set the following data here according to the actual situation£º

Site number£ºAdd a new site number

Hardware of field acquisition cardid£ºAccording to the actual hardware of the field acquisition cardidNo. to fill in£¬£´Digit number£¬Be true and correct£¬otherwise£¬The system will not communicate properly¡£

Concrete pouring time£ºCan fill in¡¢Or not.£¬As a note only¡£

Sensor enable£ºAccording to the¡°Field data collector¡±Actual sensor configuration on£¬Select the sensor bit to use¡£

Please note that£º¡°Field data collector¡±The sensor numbers on are sequential£¨Or not in order£©¡£

nEnable this station£ºDetermine if the station is enabled¡£

nAdjust the position of each station£ºAfter pressing this button£¬Drag the site to be adjusted with the mouse£¬To change its position in the drawing¡£

nSet parameters of each station£ºAfter pressing this button£¬Click the site to be adjusted with the mouse£¬You can reset the parameters of this site¡£

nDelete a station£ºPress this button£¬Click todeleteSite£¬Pop up the delete site dialog box£º

click¡°Determine¡±£¬Delete it¡£

nSave and enter the main interface£ºSave the settings just made and enter the main interface of the software¡£

nSign out£ºExit the software¡£

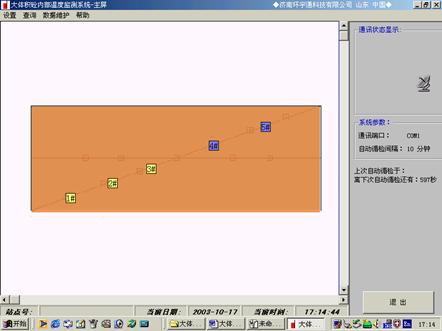

nMain operation interface£º

nUse of menus

nSetup menu

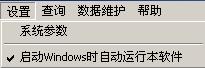

click¡°Set up¡±Under the menu¡°system parameter¡±

nAdjust date time £ºThis function provides¡°Counter table¡±function£ºThe system time can be adjusted manually.£¬To make the date and time of the computer match the actual date and time at that time¡£

nCommunication parameter setting

¡°Communication port¡±It can be set according to the actual situation.£¬Select port¡£Recommended here¡°Automatic acquisition¡±Button£¬After pressing the button£¬The system displays the following prompt£º

Follow the prompts£¬The configuration of communication port can be completed automatically.¡£

¡°push parameter¡±£ºPlease use the default value¡£

¡°Acceptance parameter¡±£ºPlease use the default value¡£

nSet the automatic inspection interval You can set the automatic inspection interval according to your own needs¡££¨Default is recommended£º30Minute£©

nSign out You can quit.¡°system parameter¡±Set up

nstart-upwindowsRun the software automatically when

It's a switch menu.£¬You can set whether to startwindowsRun the software automatically when¡£If set to¡°yes¡±£¨Check mark£©£¬You can run the software automatically the next time the computer starts£¬And enter the main interface¡£

nParameters of each monitoring point

Set the position of each monitoring point¡¢number¡¢HardwareID¡¢Sensor configuration¡¢Site enabling status, etc.£¬Please see¡°system maintenance¡±¡£

nAlarm temperature difference setting

The temperature difference alarm threshold between adjacent sensors connected to the same data collector can be set¡£The scope is0reach99£¬The default value is25degree¡£The alarm prompt is as shown in the figure.£º

nEnable automatic data backup

The checkmark in front of the menu always works£¬Every day11£º59and23£º59Around the clock£¬Automatic backup of measurement data¡£This is specially set for data security¡£

click¡°Set up¡±Under the menu¡°system parameter¡±

nQuery menu

Click on the site in the drawing£¬The same menu will appear¡£

nParameter setting of the station£ºAfter selecting a station£¬Click this button£¬Parameters of the station can be set.¡£

nImmediate inquiry£ºAfter selecting a station£¬Click this button£¬The temperature of the station can be queried immediately¡£

nQuery all sites now£ºClick this button£¬The temperature of each enabled site can be queried immediately¡£

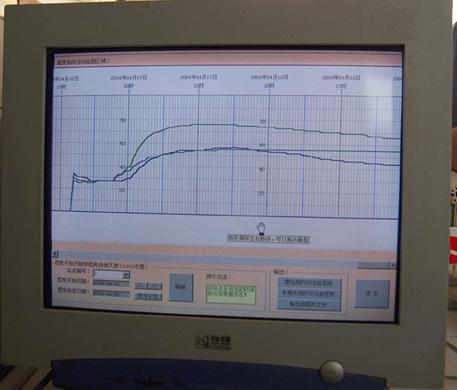

nMeasured temperature curve£ºClick this button£¬It can display the£¬Plot of the actual measured temperature at the site£º

Print pattern£¨Reduction£©

Print pattern£¨Reduction£©

In the figure above, you can¡°Setting of drawing start date and drawing duration days¡±£»You can choose how to output£¨Original scale prints the current drawing£»Half width scale prints the current drawing¡¢Output to picture file, etc.£©¡£

In the above picture£¬You can drag left and right with the mouse£¬To change the position of the current view£¬You can also use the scroll bar below the graphic£¬To change the position of the current view¡£

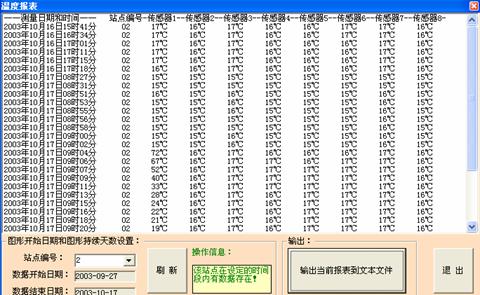

nReport form£ºclick¡°Report form¡±Button£¬The following screen appears(Resolution up to0.1)£º

In the figure above, you can¡°Graph start date and graph duration days¡±Set up¡±£»Sure¡°Output current report to text file¡±£¬Then print out¡£

nView the main configuration of each site£ºHere you can see the detailed configuration of each site¡£

nBe careful£ºClick on each site of the main operation interface£¬Can be set or queried£¬As shown in the figure£º£¨The specific operation is the same as above£©

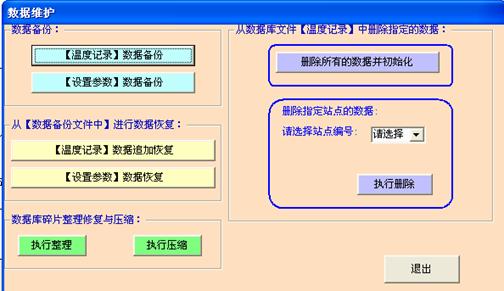

nData maintenance menu

click¡°Data maintenance¡±Lower¡°Data maintenance¡±

nData backup

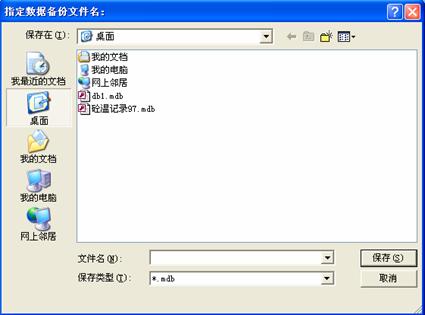

¡¾Temperature recording¡¿Data backup£ºYes, yes.¡°Temperature recording¡±Data for backup¡£The specific operation is as follows£º

Click this button£¬Eject¡°Specify data backup file name¡±Dialog box£º

In the figure above, you can name and save the file to be backed up.£»click¡°Preservation¡±Button to save¡£

n¡¾Setting parameters¡¿Data backup£ºYes, yes.¡°Setting parameters¡±Data for backup¡£

The specific operation is the same as above¡£

nfrom¡¾In the data backup file¡¿Data recovery

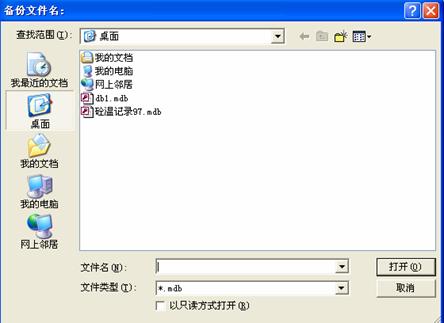

n¡¾Temperature recording¡¿Data append recovery£ºYou can append previously saved data to¡°Temperature recording¡±Database

Click this button£¬Eject¡°Backup filename¡±Dialog box£º

Find previously saved data files£¬click¡°open¡±Button£¬Then you can append the data to the current¡°Temperature recording¡±Database¡£

¡¾Setting parameters¡¿data recovery£ºCan be restored to previously saved¡°Parameter setting¡±state¡£

The specific operation is the same as above¡£

nDatabase defragmentation repair and compression

nExecution and arrangement£ºDefragment database files¡£

nExecution compression£ºCompress database files¡£

nFrom database file¡¾Temperature recording¡¿Delete the specified data in£º

nDelete all data and initialize£ºDelete existing¡°Temperature recording¡±All data in the database£¬And initial database to empty state¡£

nDelete data for the specified site£ºstay¡°Please select a site number¡±Select the number of the site to delete from the drop-down list£¬click¡°Execution deletion¡±You can¡°Temperature recording¡±Delete all data from the specified site in the database¡£

nSign out£ºSign out¡°Data maintenance¡±window

nHelp menu£¨slightly£©

nOther instructions£º

nAfter the software enters the main interface£¬That is to say, it can automatically and regularly check£¬It can be changed by setting the periodic inspection interval.¡°Timing interval¡±¡£Default is recommended£¨30Minute£©¡£

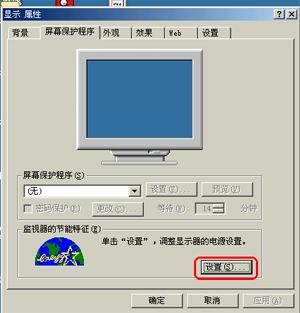

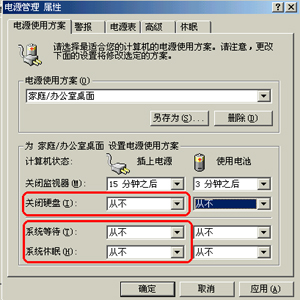

Please pay special attention£ºOn the computer¡°Power management¡±Attribute£¬take¡¾System sleep attribute¡¿and¡¾Close hard disk¡¿attribute¡¢¡¾System standby properties¡¿All set as¡°never¡±¡£otherwise£¬It is possible that your computer will automatically go to sleep or the hard disk will not work£¬The software can not be automatically checked¡£To do this, right-click the blank space on the desktop of the system.£¬Appear¡°Display attribute¡±£º

Click on¡°Screen saver¡±option£¬Then click¡¾Set up¡¿£¬Appear¡°Power management¡±attribute£¬Pictured£º

Please send¡°Close hard disk¡±¡¢¡°System dormancy¡±Property set to¡°never¡±£¬System standby is not allowed¡¢dormancy¡£

nDuring the measurement period£¬¡¼Computer software¡½and¡¼Field data collector¡½¡¢¡¼Data adapter¡½All in working condition¡£

nAfter each query£¬If there is communication failure£¬Fault information will be displayed automatically£¬You should find out the cause of the faulty site£¬Generally, the following items need to be checked£º£±¡¢Corresponding to this site¡¼Field data collector¡½HardwareIDIs the number correct£¬2¡¢Is it broken?£¬3¡¢Short circuit£¬4¡¢¡¼Field data collector¡½Damaged or not¡£

Emphasize£ºBecause the equipment is used on the construction site£¬Poor working environment£¬To prevent equipment and cables from being damaged¡¢Squash¡£In case of communication failure£¬Be sure to find out why£¬Timely repair¡£When arranging communication cables£¬Place it in the wet concrete surface£¬It's a particularly effective way.£¨If it goes along the steel bar£¬Will be better£©¡£Another way is to thread the wire into the plastic pipe¡£

No joint is allowed in the middle of the cable£¬If it can't be avoided£¬Ensure reliable connection at the joint£¬All joints must be waterproof¡¢Anti short circuit¡£

n¡¼Field data collector¡½Wooden case should be added outside for protection£¬Prevent the ambient temperature from overheating£¬To prevent¡¼Field data collector¡½Be rolled¡£Outside the wooden box£¬Put on a plastic bag£¬It can effectively avoid rain and splashing¡¢Dew¡£Always avoid flooding¡£

nThe¡¼Field data collector¡½Cascade function,Theoretically, it can be cascaded at most255individual¡£The most practical cascading instances that have been applied in the construction site are44individual¡£

nThe¡¼Field data collector¡½and¡¼Data adapter¡½The distance between them should not be greater than1km£¨Related to the section and quality of data lines£©, ¡¼Data adapter¡½and¡¼Computer¡½The distance between them is not greater than5m¡£

The following features need to be customized to provide£º

nThe customization function of the software can be provided throughInternetFunction of remote viewing curve and data report£¨To use this feature£¬Need1¡¢The computer running the temperature measurement system should be connected to theInternet,2¡¢Need internetIPAddress support/Or rent our server/Or useEmail£©,if necessary£¬Please contact our technical department¡£

nThe customization function of the software can be provided throughInternetFunction of sending data to designated mobile phone via SMS£¨To use this feature£¬The computer that needs to run the temperature measurement system should be connected to theInternet£©£¬if necessary£¬Please contact our technical department¡£

nThe customization function of the software can be provided throughGSMFunction of module card to send data to designated mobile phone via SMS£¨To use this feature£¬Additional purchase requiredGSMModule card¡¢Mobile user card£©£¬if necessary£¬Please contact our technical department¡£

nThe software has been added with any custom logic function.£¬Used to control the heat source, such as£ºElectric blanket¡¢Steam valve¡¢Automatic opening and closing of hot air blower, etc.¡£Need to cooperate with our company's remote control relay control¡£

Edition£¨Software and hardware upgrade at the same time£©History£º1994,1995£¬1997£¬2001£¬2003£¬2005£¬2007.

technical parameter£º

data collector£º£¨Industrial standard£©

£±¡¢Working environment temperature of equipment£º££²£°¡æ¡«£¸£°¡æ£»

£²¡¢measuring range£º-15¡æ¡«125¡æ£¨2005year2month1Daily adjustment£©£¬At the measured temperature<-19¡æTime£¬display£Ì£Ì£¬At the measured temperature>129¡æTime£¬display£È£È£»

£³¡¢Distance from data adapter£ºCross section of data line>1mm2Time£¬The measured distance value is1000mRange£»If the distance is too long£¬The data bus between the data adapter and the first field data collector can be appropriately bold.CLine andDLine£¬Some of our customers are connected in parallel.CLine andDLine£¬The effect is very good.¡£

£´¡¢Maximum number of sets£ºData collectors connected to the same data adapter are best controlled in£³£²Only within£»

£µ¡¢Number of sensors that can be connected per data collector£º£±¡«£¸individual£»

£¶¡¢Data collector to sensor length£º£°¡«£±£°m£»£±£±¡«£³£°m£¨Customized£©£»

£·¡¢Power supply mode£ºData adapter bus parasitic£»

£¸¡¢Measurement method£ºAutomatic inspection£¯Trigger inspection£»

£¹¡¢Eight wayADTotal time of measurement conversion<1s,Data resolution accuracy0.01,Effective1.00£¬error<=¡À1¡æ¡À1word£»

Data adapter£º

¡¡¡¡£±¡¢Working environment temperature of equipment£º££²£°¡æ¡«£¸£°¡æ£¬Place next to computer£»

¡¡¡¡£²¡¢Interface with computer£ºSupport at the same time£Ã£Ï£ÍMouth and£Õ£Ó£Âmouth£¬Automatic adaptation£»

£³¡¢Distance from computer<=£¸m,Distance from field data collector<=1200m

£¨Related to data line£©£»

£´¡¢supply voltage£º£Á£Ã170£Ö¡«240£Ö,50¡«60£È£Ú£¬Market electricity£»

£µ¡¢Data receiving and sending instructions£»

£¶¡¢What is provided to each data collector through the data bus is14.8VSafety voltage of£»

£·¡¢Data adapter has short circuit automatic protection function£»

Jinan huanyutong Technology Co., Ltd.

Email: ywjn@0531hyt.com

website1£ºhttp://www.0531hyt.com

Linear telephone:(0531)8715-6618

Automatic fax server:(0531)8716-2717

To work in an office:Jinan Jiwei Road90Number1#Commercial building